Gochang, South Korea, September 3, 2025

News Summary

Korea Electric Power Corporation has introduced S-CAP, a data-driven software tool that standardizes submarine cable protection by quantifying risk, recommending optimized protection measures and producing design reports. S-CAP accepts site-specific inputs such as anchor types, wave and current conditions, and detailed seabed properties to calculate variable burial depths and recommend alternatives like rock berms or concrete ducts. Backed by numerical modelling and full-scale tests at a large Korean testing centre, the program has received formal document verification and has been applied to a major offshore wind grid link, delivering improved transparency, lower repair risk and cost savings.

KEPCO launches data‑driven tool to standardize and optimize submarine cable protection; DNV verification and real projects follow

A new software tool from Korea Electric Power Corp. aims to make submarine cable protection more scientific, repeatable and cost‑efficient. The KEPCO Submarine Cable Protector, known as S‑CAP, standardizes design, quantifies risk and recommends protection measures for offshore power and telecom cables. The program has received formal document verification from a global classification body in February 2024 and has already been applied to a major Korean offshore wind grid link.

What the software does and why it matters

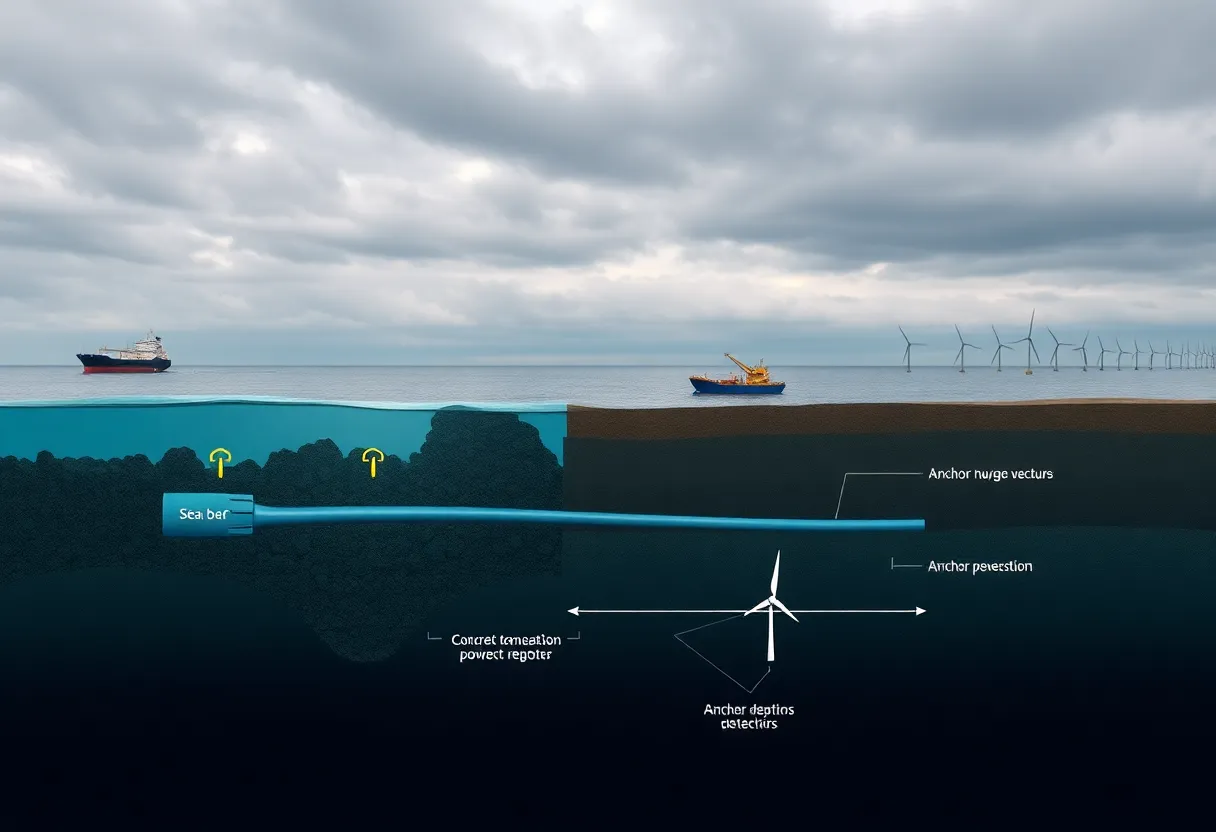

Submarine cables connect offshore generators and data networks to onshore demand centers and are now being built faster worldwide because of the energy transition and growing data needs. That growth has exposed the limits of legacy protection methods, which often rely on simple rules of thumb or uniform burial depths. S‑CAP turns protection into a data‑driven design process by taking site conditions and operational risks as inputs and producing quantified, optimized protection plans.

- S‑CAP accepts environmental and engineering inputs such as anchor types and weights, wave height, current speed and detailed seabed properties (unit weight, undrained shear strength and internal friction angle).

- The program calculates optimal burial depth for each route segment, suggests multiple protection options and recommends the most suitable choice.

- S‑CAP produces cross‑section drawings and a full design report to improve transparency and traceability.

How the approach differs from conventional practice

Conventional cable protection often uses trenching and burial in soft seabeds, and rock berms or concrete ducts where burial is impractical. But design criteria for those alternatives are not standardized globally. Many legacy approaches call for fixed burial depths — for example a flat 1.5‑m minimum — or depend on the Burial Protection Index, which can be hard to apply to layered seabeds. S‑CAP applies variable burial depths keyed to local risk and uses quantified standards for protective structures to avoid overly conservative or inadequate designs.

Testing and engineering basis

The software is backed by extensive numerical modeling and full‑scale tests conducted at KEPCO Research Institute’s Gochang Power Testing Center. The site includes transmission testing lines and underground cable verification facilities across roughly 741,000 sq m. From those tests, KEPCO adopted a core design principle: required burial depth must exceed maximum anchor penetration plus a safety margin. That empirical finding was converted into engineering standards and formula‑based charts for use in S‑CAP.

Verification and claimed benefits

S‑CAP received document verification from a major classification and certification body in February 2024, marking a formal assessment of its scientific methods and real‑world applicability. The software is intended for both HVDC and AC submarine cables across offshore wind farms, cross‑border HVDC corridors and other interregional links. Claimed practical benefits include improved structural integrity, reduced repair risk, and lower environmental impact during installation. In cost terms, the tool is reported to cut construction spending by about 5% — roughly USD $2 million per 100 km — and in one Korean wind‑to‑land connection project S‑CAP implementation is said to have reduced installation costs by around 50%, equal to approximately USD $3.6 million.

Where S‑CAP has been used

KEPCO applied S‑CAP to its Southwestern Offshore Wind‑to‑Land Connection project, a multi‑year grid link targeted for partial grid connection in 2029 and final completion by 2031. The digitized reports and clear design logic are credited with improving contractor‑owner trust and minimizing environmental disturbance during installation.

Wider submarine cable projects in the region

The same period has seen major subsea cable developments in East Asia and across the Pacific. A consortium led by a South Korean cable manufacturer has secured a roughly 260 km undersea telecom link between Busan and Fukuoka, expected to finish by 2027. That project, delivered on an EPC basis, is positioned to boost cross‑border connectivity and handle rising AI and cloud data loads in the region.

Separately, construction has begun on the E2A subsea cable connecting East Asia and the United States. The E2A route will be about 12,500 km, land at Toucheng (Taiwan), Busan (South Korea), Maruyama (Japan) and Morro Bay (California), and offer more than 192 Tbps across 12 fiber pairs. The system will use 18 kV powering and is scheduled to go live in the second half of 2028. The E2A consortium includes multiple regional and international network operators.

Industry context and risk reduction

Recent submarine cable incidents have shown how costly and disruptive repairs can be and how failures can threaten stable supply and communications. Protecting cables requires accounting for dropped or dragged anchors, changing water depth and currents, wave energy and seabed composition. S‑CAP is presented as a holistic, field‑tested system that integrates quantified standards for burial and protective structures — such as rock berm dimensions and installation tolerances — to reduce both physical risk and long‑term costs.

Next steps and applicability

The software is positioned for broad use across offshore wind, HVDC corridors and telecom projects. Its creators say it improves documentation and creates a consistent design logic that owners, designers and contractors can follow. As submarine networks multiply, tools that combine engineering tests, numerical modeling and standardized criteria may play a growing role in lowering repair risk and cost while ensuring safe delivery of power and data.

FAQ

What is S‑CAP?

S‑CAP is a software program that standardizes submarine cable protection design by taking environmental and engineering inputs and producing quantified burial depths and protection recommendations.

How does it decide burial depth?

The program uses site‑specific inputs such as anchor characteristics, waves, currents and detailed seabed properties. Its design rule requires burial depth to exceed the maximum anchor penetration plus a safety margin.

Has it been tested and verified?

Yes. The software is based on numerical simulations and full‑scale tests at a large testing center. It also received formal document verification from an international classification body in February 2024.

What savings and benefits are reported?

Reported benefits include improved design accuracy, better traceability and lower costs. Claimed savings include about 5% per 100 km (roughly USD $2 million) and larger savings in individual projects where variable protection replaced overly conservative measures.

Are other major subsea projects under way in the region?

Yes. A 260 km Busan–Fukuoka telecom link is planned for completion around 2027, and the E2A trans‑Pacific cable (about 12,500 km) is under construction for service in the second half of 2028, among other projects.

Key features at a glance

| Item | Detail |

|---|---|

| Software | S‑CAP (KEPCO Submarine Cable Protector) — data‑driven protection design tool |

| Verification | Document verification from a global classification body in February 2024 |

| Testing site | Gochang Power Testing Center — ~741,000 sq m with high‑voltage and cable test facilities |

| Core design rule | Burial depth must exceed maximum anchor penetration plus safety margin |

| Reported cost impact | Approx. 5% savings per 100 km (~USD $2M) and an estimated USD $3.6M (50%) on one wind link project |

| Busan–Fukuoka link (JAKO) | ~260 km undersea telecom cable; expected completion by 2027; delivered on EPC basis |

| E2A trans‑Pacific cable | ~12,500 km; >192 Tbps over 12 fiber pairs; landing points in Taiwan, South Korea, Japan and California; service H2 2028 |

Deeper Dive: News & Info About This Topic

Additional Resources

- Korea JoongAng Daily: LS Cable wins $115M submarine cable order from Taiwan

- Wikipedia: LS Cable & System

- Capacity Media: LS Cable joins Korea–Japan submarine cable project

- Google Search: Korea Japan submarine cable Busan Fukuoka

- Financial Times: Subsea cable / industry coverage

- Google Scholar: submarine cable protection anchor penetration

- DataCenter Dynamics: Construction begins on E2A subsea cable connecting US to Asia

- Encyclopedia Britannica: E2A subsea cable

- Inspenet: Taihan secures subsea cable contract for Korea offshore wind project

- Google News: Taihan subsea cable Korea offshore wind

Author: Construction FL News

The FLORIDA STAFF WRITER represents the experienced team at constructionflnews.com, your go-to source for actionable local news and information in Florida and beyond. Specializing in "news you can use," we cover essential topics like product reviews for personal and business needs, local business directories, politics, real estate trends, neighborhood insights, and state news affecting the area—with deep expertise drawn from years of dedicated reporting and strong community input, including local press releases and business updates. We deliver top reporting on high-value events such as the Florida Build Expo, major infrastructure projects, and advancements in construction technology showcases. Our coverage extends to key organizations like the Associated Builders and Contractors of Florida and the Florida Home Builders Association, plus leading businesses in construction and legal services that power the local economy such as CMiC Global and Shutts & Bowen LLP. As part of the broader network, including constructioncanews.com, constructionnynews.com, and constructiontxnews.com, we provide comprehensive, credible insights into the dynamic construction landscape across multiple states.